Well after all the pressure to print a friends parts for his 3D printer build my poor little Replicator Dual from 2012 spat the dummy and broke a belt.

Took a bit but I managed to print a clip as a temporary replacement. Not pretty but very effective.

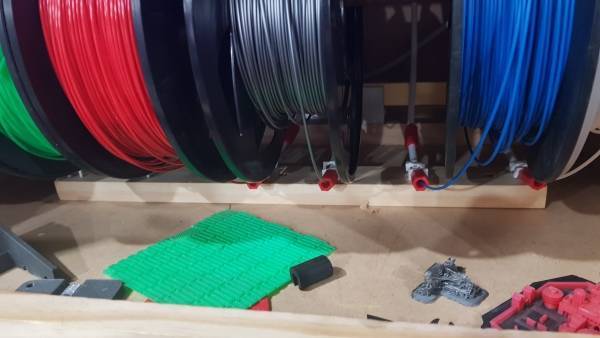

Since I was at it I decided I may as well add some guides to the filament spools.

The spools travel up the back of the printer in guide tubes but there was enough drag to cause the occasional print fail.

I decided to add bearings but needed to create a sleeve so that they could insert snugly into the roll.

The first few attempts were a fail as I had the tolerances too tight but quickly discovered that if I inserted the bearing into the print while the filament was still hot I achieved a very tight fit.

While there is a little bit of a wobble on the larger rolls this will do for now. Not bad for $20

You must be logged in to post a comment.